Lithium-ion batteries is widely applied in secondary energy sector such as mobile electronic devices and transportation vehicles due to high energy density. Current commercial anode can hardly meet the requirements of high energy density, while new anode materials during the process of cycling have some bottleneck problems of volume expansion and low conductivity, which seriously affect the battery cycle life. Our group has been exploring the field of lithium-ion battery anode for many years. For the failure of pulverization of electrode materials caused by volume expansion during the energy storage process, combining plasma physics and chemically controlled reaction, our group has designed and synthesized carbon-constrained nanostructures to provide solutions for the structural confinement and effective charge transfer of active materials. In recent years, many scientific achievements have been made and several academic papers have been published in international core journals. (Nano Energy, 2017, 31:74-83;ACS Nano, 2018, 12, 8037-8047; Mater. Today Energy, 2020, 17, 100439-100447; Applied Surface Science , 2021, 550(32):149247, etc.)

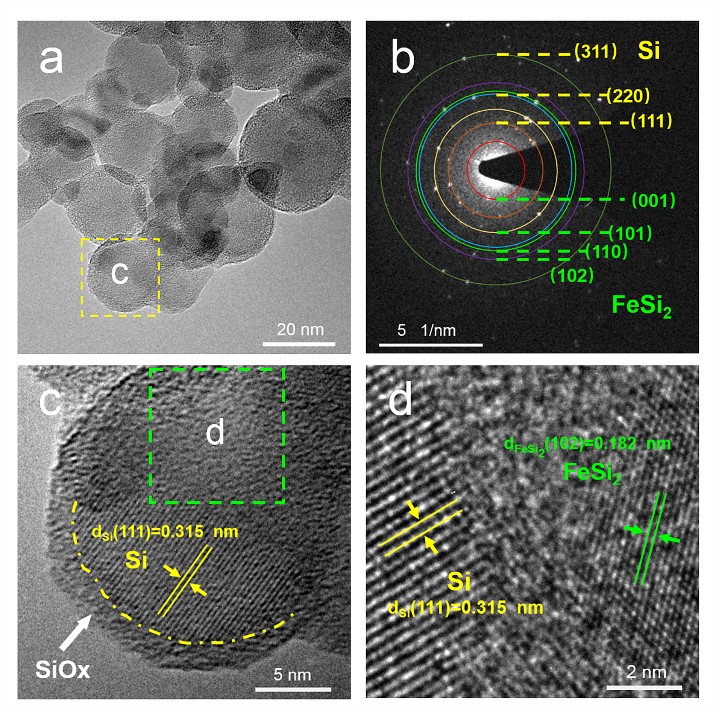

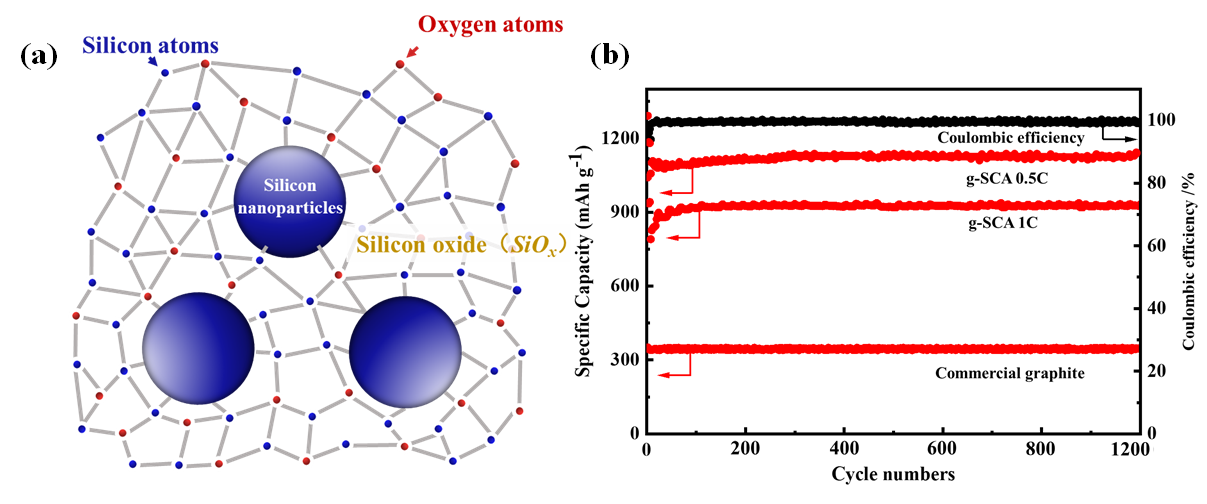

Silicon-based materials are ideal anode for next generation high energy density lithium-ion batteries due to their abundant reserves, high theoretical specific capacity and low operating potential. However, the two-phase lithiation mechanism between α-Si and α-LixSi at room temperature is responsible for the huge volume expansion of silicon-based materials. To solve the bottleneck problem of serious bulk expansion, low compaction density and initial coulombic efficiency of silicon-based anode materials, this team proposed propose a novel structure of FeSi2-Si eutectic nanoparticles protected by the SiOx shell (Figure 1). SiOx encapsulated FeSi2-Si eutectic nanoparticles exhibit excellent capacity of 674.9 mAh/g after 500 charge/discharge cycles, and the capacity retention rate is above 90% after the stabilization process. This work provides a solution for the long-lasting cycling of high-performance silicon-based anode materials for lithium-ion batteries. To further alleviate the material shattering and unstable solid electrolyte interface caused by the volume expansion of small-sized silica nanoparticles during lithiation, this team used high-energy plasma to evaporate the silicon target into gaseous silicon, which coalesced into amorphous silicon covered silica nanoparticles under a certain temperature gradient. And after the process of precisely controlled oxygen for passivation, the amorphous silicon oxidized to SiOx, forming a unique composite nanostructure of nano Si covered by SiOx. The developed high specific energy silicon/carbon anode material can reach a specific capacity of over 1000 mAh/g at 0.1C and over 800 mAh/g at 1C with a stable cycle time of 1200 cycles (Figure 2). The high specific capacity Si/C anode material is recognised as the ideal route to the next generation of anode materials due to its higher ICE and cycle life, compared to the other Si/C anode materials on the market. The above related results were published in Mater. Today Chemistry, 2021, 21: 100540 and other well-known journals in China and abroad.

Figure 1. Morphological and compositional characterization of SiOx-encapsulated FeSi2-Si eutectic nanoparticles

Figure 2. (a) Schematic diagram of silicon structure; (b) high specific energy silicon/carbon electrochemical properties

Industrialisation results:

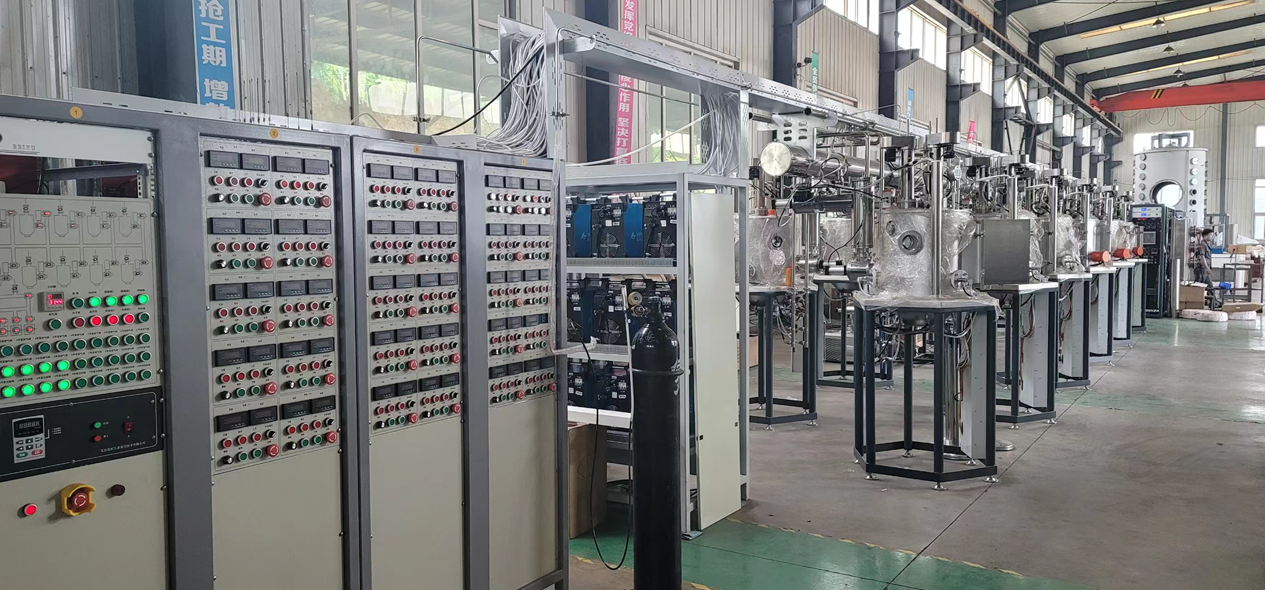

This team used plasma physical preparation method to synthesize silicon-based alloy high performance nanoanode materials and realized the technology of silicon-based alloy high performance nanoparticles mass production. This team has developed a silicon alloy electrode material with a specific capacity of 1400 mAh/g at 0.1 A/g and 500 cycles, which is expected to control the cost of silicon based alloy nano electrode material to less than 170,000/ton; joint pilot test with mainstream automobile manufacturers for high specific energy Si/C anode material, and designed and developed the high specific energy Si/C anode material and the cobalt-free lithium-rich manganese cathode material were assembled into a full battery, and the maximum energy density was 440 Wh/kg at a current density of 0.1 C. The production cost of this high specific energy gas condensed Si/C anode material can be reduced to 150,000 RMB/ton (320,000 RMB/ton for commercial use). It is expected that after about two years of certification and production ramp-up, this high energy gas condensed Si/C anode material will enter the industrialization process and be applied to the electric vehicle sector on a large scale.

Figure 3. High-energy silicon/carbon cathode material mass production equipment