In response to the pain points of low quality, high cost and low production efficiency of domestic nanopowders, Key Laboratory of Energy Materials and Devices (Liaoning Province) has successfully developed high-quality, low-cost and high-efficiency plasma evaporation nanopowder mass production equipment and process with independent intellectual property rights through a series of technical improvements, starting from both equipment and process. The process has realized the automated production from raw materials to finished products. At present, a series of key technologies in the continuous mass production of nanoparticles, such as arc source control, current and voltage settings, powder collection technology, passivation process, particle size and morphology control, have been overcome, and the daily kilogram-scale mass production of various types of nanopowders has been realized. Dynamic adjustment of nanoparticle structure and composition reengineering have been realized by designing gas-phase or liquid-phase reactions. The key engineering problems in the low-cost, large-scale and structure-controlled growth of nanoparticles have been solved to meet the market demand for high-volume, high-quality and low-price nanopowder supply.

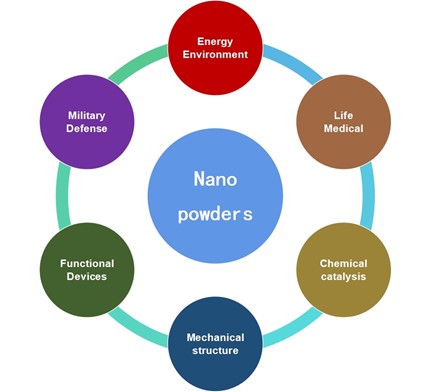

The laboratory takes the industrialized production of nano-powder as the entry point, breaks through the three major development bottlenecks of nano-powder quality, cost and scale, unites the equipment, technology and application development at home and abroad, and has been successfully applied to the key materials of magnetorheological fluid, high-performance gas-condensed silicon/carbon lithium-ion battery anode materials, high-performance lithium-rich manganese-based lithium-ion battery cathode materials and nano-modified low-temperature rubber, and later will gradually develop the aerospace In the future, we will gradually explore the fields of aerospace, military defense, physical energy storage, life science and medical care, chemical catalysis, etc. We will establish a comprehensive industrial platform covering materials, applications and equipment development to help upgrade the domestic manufacturing industry.

Figure 1. (1) Metal monomer and multi-alloy nanoparticle powders (Fe, Ni, Sn, Fe-Sn, Ni-Si, etc.); (2) Carbon materials (graphene, carbon nanotubes);(3) polymorphic silicon nanopowders; (4) carbon-coated composite nanoparticle powders, (Fe@C, Sn@C, Fe-Sn@C, etc.); (5) non-metallic nanoparticle powders (SiC, TiC, TiN, TiO2)

Electric arc ion plating conductive corrosion resistant coating industry technology and equipment

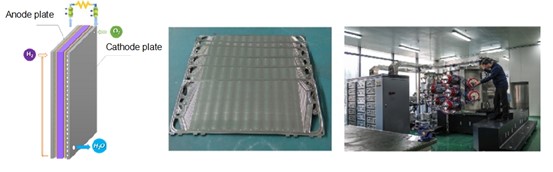

1.Fuel cell bipolar plate conductive corrosion resistant coating

Cost and lifetime are the main bottlenecks that limit the large-scale commercialization of fuel cells. Among them, bipolar plates are one of the important components of fuel cells, and the cost accounts for 40%-50% of the overall fuel cells, which severely restricts the large-scale application of fuel cells. Stainless steel bipolar plates have advantages in terms of cost and processing and forming, but their easy corrosion characteristics seriously affect the conductivity and durability of fuel cells. For China's major needs in hydrogen energy new energy vehicle technology, Liaoning Energy Materials and Devices Key Laboratory focuses on the development of materials, processes and equipment for the modification of fuel cell bipolar plates with special conductive and corrosion-resistant precision coatings, using pulsed bias arc ion plating technology to coat carbon chromium nanocomposite films for surface modification of stainless steel bipolar plates, its performance indicators in conductivity, corrosion resistance and hydrophobicity have reached international Leading level, the laboratory in order to improve the overall quality of the coating yield, has developed to meet the annual output of tens of thousands of processing needs of the production line, the capacity of: 1 furnace every 1.5 hours; each furnace double-sided plating 40 pieces, single-sided plating 80 pieces; 400-500 pieces per day, more than 10,000 pieces per month continuous production capacity. It plays a key technical support role for the independent innovation of the whole process from originality to industrialization of China's hydrogen energy new energy vehicles.

2. High corrosion resistance and strong heat dissipation coating technology

Efficient heat dissipation and salt spray corrosion resistance are the core problems faced in the fields of electronic information, aerospace, and safety energy storage. Aluminum alloy has become the best shell material for high heat generation rate components because of its excellent physical properties and low cost. However, the radiation heat dissipation ability of aluminum alloy is very poor and cannot meet the engineering heat dissipation demand. In response to the above problem our team designs a double-layer structure coating by arc ion plating technology, using the strong salt spray resistance of titanium alloy, combined with the high thermal conductivity, high radiation rate and super hydrophobic properties of amorphous carbon and nano-metal composite, to transfer the surface heat of high temperature devices into the coating and radiate to the outside world in the form of infrared rays, accelerating the heat exchange between the device and the outside world and reducing the surface and internal temperature of the device, thus achieving The effect of improving the stability and service life of the device has achieved an innovative breakthrough in the field of non-high temperature, radiation cooling theory application, and opened up a new way of radiation cooling for thermal management.

In the application, the actual application of the grid 3 and 2 heat sinks prepared by the coating modification is remarkable, and the temperature rise of CPU is always controlled within 94°C at 100% usage, and the optimal sample can be controlled within 92°C to meet the application requirements. Under the national standard salt spray resistance test standard of 96 h, the surface of the sample does not have any corrosion phenomenon.

The team has made important progress in modified coating materials and preparation process, and can design and process special coating production and processing lines for different sizes of heat sink substrates to achieve mass production and processing of different kinds of high corrosion resistant and strong heat sink coatings to meet the universal heat sink needs faced by various fields.

Thin film electrode material magnetron sputtering winding continuous production technology

At present, there is a big gap between the quality and performance of domestic supercapacitor electrode film materials and foreign countries, and how to improve product performance, reduce cost and improve the process preparation level are painful issues of great concern to the industry. The most difficult part of film electrode preparation is that there is almost no "off-the-shelf" equipment and process to be used. The plasma physical method and later chemically controlled modification are used to design and prepare additive-free large-area single-component or multi-component supercapacitor electrode thin film materials. Using the principle of magnetron sputtering, the material on the target is sputtered onto the coiled substrate to form a film layer by supplying the material to the target under vacuum conditions, generating plasma and controlling the motion of the plasma with a magnetic field. The technology has the following features: (1) it can produce high purity, high film quality thin film electrode materials with high production efficiency; (2) it can make a variety of different materials into composite thin film electrodes, allowing multiple coating sources (metals, alloys, dielectric materials) to be coated simultaneously, and each functional film layer can be grown in one highly integrated multi-chamber equipment in one step without breaking the vacuum (3) Fine control of film material composition and structure, precise control of process, bi-directional winding design, continuous production process of key electrode materials on a large scale, and mass production of high power electrode materials for supercapacitors. Meanwhile, this continuous coating system is also suitable for coating processing lines in various fields such as photovoltaic and semiconductor.

Figure 1. Magnetron sputtering production thin film electrode mechanism diagram and horizontal continuous winding coating equipment (production line object diagram provided by equipment partner Shenyang Beiyu Vacuum Equipment Company)