In response to the pain points of low quality, high cost and low production efficiency of domestic nanopowders, Key Laboratory of Energy Materials and Devices (Liaoning Province) has successfully developed high-quality, low-cost and high-efficiency plasma evaporation nanopowder mass production equipment and process with independent intellectual property rights through a series of technical improvements, starting from both equipment and process. The process has realized the automated production from raw materials to finished products. At present, a series of key technologies in the continuous mass production of nanoparticles, such as arc source control, current and voltage settings, powder collection technology, passivation process, particle size and morphology control, have been overcome, and the daily kilogram-scale mass production of various types of nanopowders has been realized. Dynamic adjustment of nanoparticle structure and composition reengineering have been realized by designing gas-phase or liquid-phase reactions. The key engineering problems in the low-cost, large-scale and structure-controlled growth of nanoparticles have been solved to meet the market demand for high-volume, high-quality and low-price nanopowder supply.

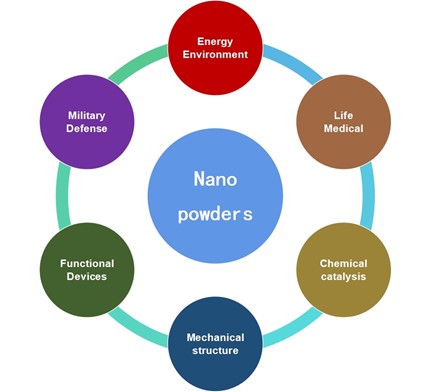

The laboratory takes the industrialized production of nano-powder as the entry point, breaks through the three major development bottlenecks of nano-powder quality, cost and scale, unites the equipment, technology and application development at home and abroad, and has been successfully applied to the key materials of magnetorheological fluid, high-performance gas-condensed silicon/carbon lithium-ion battery anode materials, high-performance lithium-rich manganese-based lithium-ion battery cathode materials and nano-modified low-temperature rubber, and later will gradually develop the aerospace In the future, we will gradually explore the fields of aerospace, military defense, physical energy storage, life science and medical care, chemical catalysis, etc. We will establish a comprehensive industrial platform covering materials, applications and equipment development to help upgrade the domestic manufacturing industry.

Figure 1. (1) Metal monomer and multi-alloy nanoparticle powders (Fe, Ni, Sn, Fe-Sn, Ni-Si, etc.); (2) Carbon materials (graphene, carbon nanotubes);(3) polymorphic silicon nanopowders; (4) carbon-coated composite nanoparticle powders, (Fe@C, Sn@C, Fe-Sn@C, etc.); (5) non-metallic nanoparticle powders (SiC, TiC, TiN, TiO2)