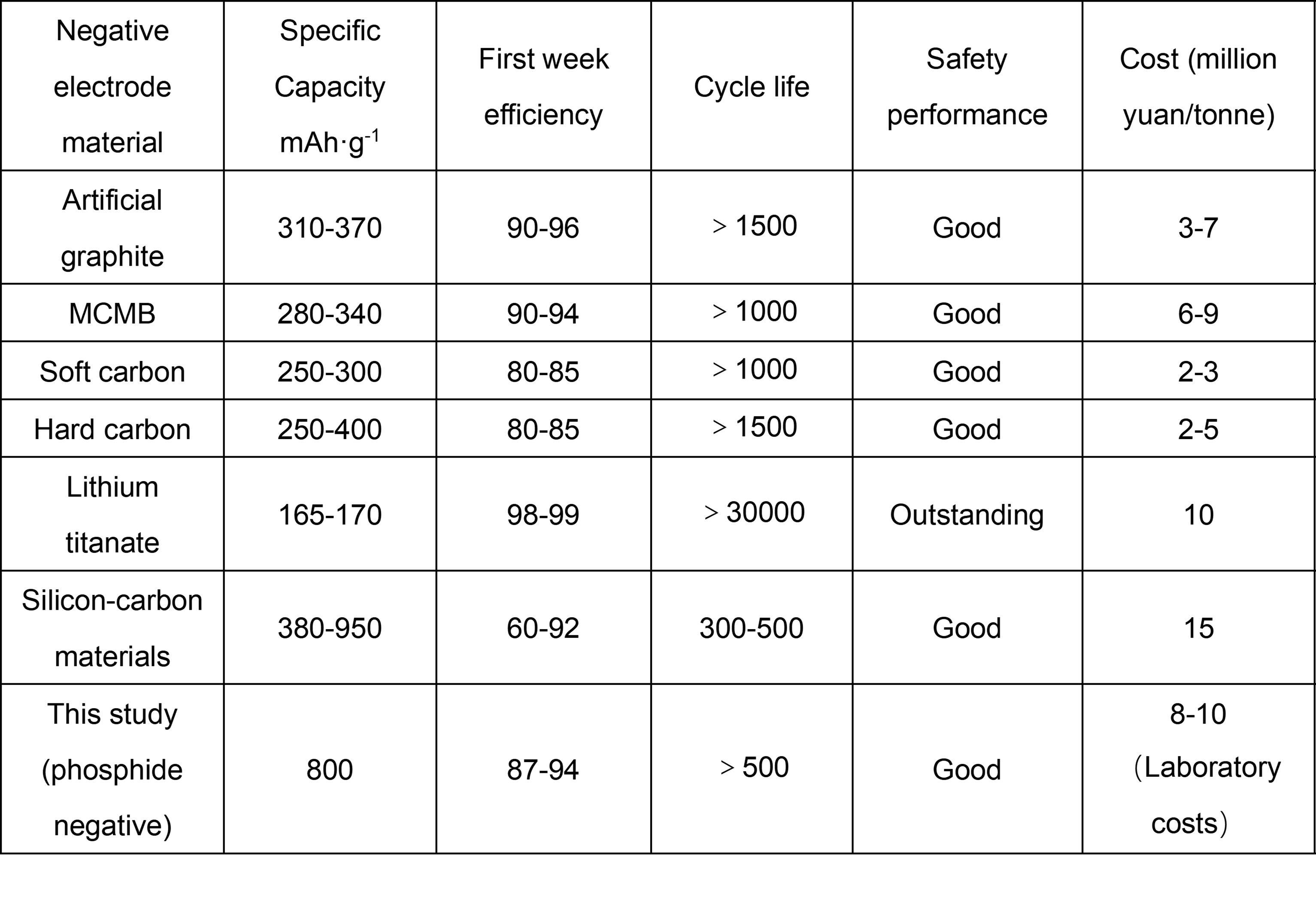

Metal phosphides are chemically intermediate between metal nitrides and metal antimonides, and they exhibit excellent electrochemical properties due to their multiple electron orbitals. With theoretical specific capacities of up to 2596 mAh·g-1 (Li3P, Na3P, K3P) and low voltage plateaus (Li/Li+, 0.8 V and Na/Na+, 0.4 V) compared to common commercial anode materials, metal phosphides are considered to be a highly promising anode material for ion batteries. However, the inherent alloying reaction mechanism of metal phosphides leads to poor cycling stability of the electrode material during charging and discharging, thus largely limiting the application of phosphide anode materials. To address the bottleneck problems such as severe bulk expansion and low electronic conductivity of phosphide nanoanode materials, this group uses the physical preparation method of hot arc plasma, combined with controlled modification of phosphorylation reactio to complete the design and fabrication of complex structure of a variety of phosphide nanoelectrodes, providing solutions for efficient energy storage and long service life of phosphide nanoactive materials. Such as core-shell type FeP2@C electrode material remains at 1132 mAh·g-1 after 500 cycles at a current density of 0.3 A g-1 (Figure 1). This is due to the fact that the fragmented FeP2 forms smaller grains and maintains distinct grain boundaries, which can increase the active interface and shorten the Li+ diffusion path. In addition, a specific progressive lithiation method of FeP2 was observed, whereby lithium ions are gradually inserted into the lattice of FeP2 to form LinFeP2, which is then converted to Li3P and Fe. The process was verified in this study by cyclic voltammetry and first-principles calculations, and the above related results were published in Mater. Today Energy, 2020, 18, 100545 Mater. Today Energy, 2020, 18, 100545, Applied Surface Science, 2021, 550, 149247 and other national and international journals.

Figure 1. Electrochemical properties of FeP2@C nanoanode materials

Industrialization results:

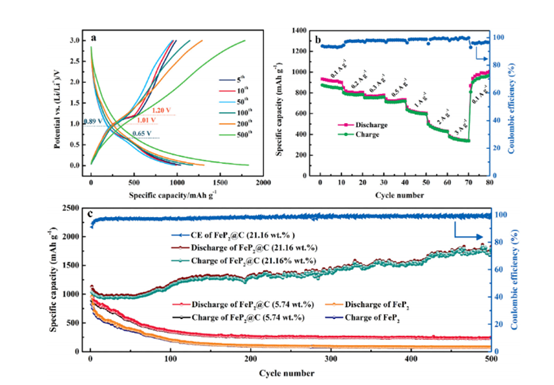

After years of exploration, our group has made breakthroughs in the research of phosphide nanoanode materials. The new nanoanode materials developed by our group can maintain a capacity of more than 800 mAh g-1 at a current density of 1 C and a cycling performance of more than 500 turns. As shown in Table 1, compared with other commonly used commercial negative electrodes, the phosphide nanoanode material developed by our group has a greater advantage in capacity and other aspects. In addition, the cost of negative electrode materials is also a serious constraint to the application of negative electrode materials. The developed phosphide nanoanode materials are moderately priced and can be mass produced with yields of 100-200 g h-1, average size (BET method) ≤ 100 nm order of magnitude, continuous operation time of mass production equipment ≥ 8 h, and product purity up to 99.9%. At present, we have conducted joint pilot tests with Great Wall Motor (Hive Energy Technology Co., Ltd.) for this anode material and reached a preliminary strategic cooperation agreement. The negative electrode is expected to be used in new energy electric vehicles.

Table 1: Comparison of the performance of commercial anode materials and new phosphide nanoanode materials