To address the critical issues of chemical stability and conductivity of metal bipolar plates for PEMFC, the original material composition design method based on cluster theory is used to design and develop a new coating material system with high conductivity and high corrosion resistance with low cost and long life as the core. The physical mechanism of conductivity and corrosion resistance is investigated in depth, and a new integrated treatment technology for bipolar plate surface gradient modification is obtained. To establish the intrinsic scientific correlation between the composition, structure and performance of coating materials, to achieve an ideal match between electrical conductivity and corrosion resistance based on revealing the mechanism of electrical conductivity and corrosion, to explore the key scientific and technical issues such as the influence mechanism of pretreatment process and coating process on the comprehensive performance of bipolar plates, and to solve the contradictory performance of bipolar plates.

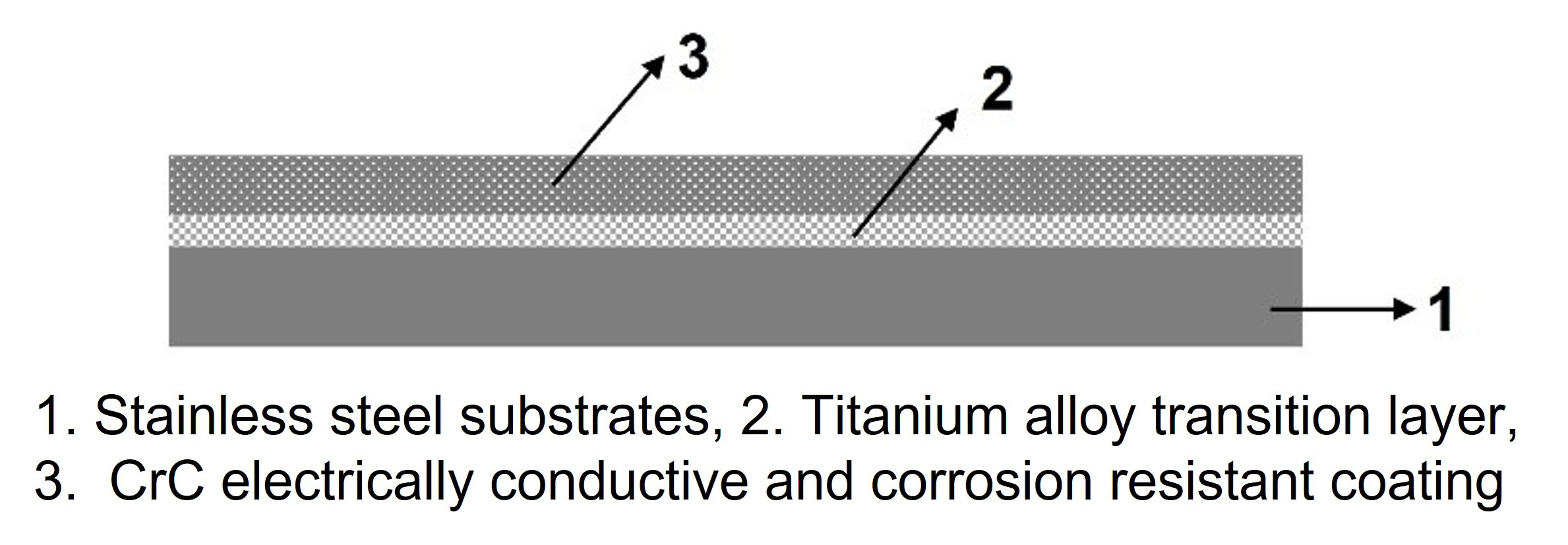

The team has developed the latest generation of "sandwich" coating structure system, which has greatly improved the sub-surface substrate and interface corrosion resistance. Through the improvement of material system and process, the coating bonding force reaches 72 N, contact resistance reaches 0.97 mΩ cm2 (flat plate) and 3.06 mΩ cm2 (flow field plate), and corrosion resistance reaches 1.3×10-7 A cm-2 (simulated battery environment), reaching the international advanced level.

The research team independently developed highly conductive, corrosion-resistant and hydrophobic coated modified metal bipolar plates, including the coating system, coating process, precision coating equipment and other sets of patented technologies. The intellectual property of the bipolar plate coating production line was licensed to Anhui Tomorrow Hydrogen Energy Technology Co., Ltd. for the industrial production of coated bipolar plates, promoting the commercial production and application of China's completely independent technology for fuel cell power reactors. The metal bipolar plate and production line for automotive fuel cells won the second prize of the first Hydrogen and Fuel Cell Technology Innovation Award of the China Automotive Engineering Society and the International Hydrogen and Fuel Cell Association (IHFCA).

Fig. 1. Schematic diagram of the sandwich coating structure