Transition metal doped electrolyte modification study:

To address the bottleneck problem of low ionic conductivity of LiPON solid-state thin film electrolytes at room temperature, the composition design of transition metal-doped LiPON is proposed. The multivalent properties and unique electronic structure of transition metals promote the formation of cross-linked network and lower the ion migration potential barrier, and provide a pioneering idea for the development of LiPON electrolyte materials to achieve high ionic conductivity. The development of novel material systems and the exploration of ion transport mechanisms provide important ideas for the design of solid-state electrolyte thin film materials with high ionic conductivity and high interfacial stability, providing effective solutions for integrated circuit components, flexible electronic devices and power-driven device applications.

The team is committed to magnetron sputtering for the preparation of nanofilms and has mastered a complete technical solution, and has accumulated rich experience in nanofilm preparation and structural tuning. The team has successfully prepared Mn-LiPON and Fe-LiPON solid electrolyte films with different doping concentrations using RF magnetron sputtering, and achieved structural composition tuning of LiPON by controlling parameters such as the number of Mn and Fe patches, air pressure and power. The ionic conductivity of the doped modified LiPON electrolyte reaches up to 1.08×10-5 S/cm, which is an order of magnitude higher than that of the original unmodified LiPON and has a great competitive advantage in this field.

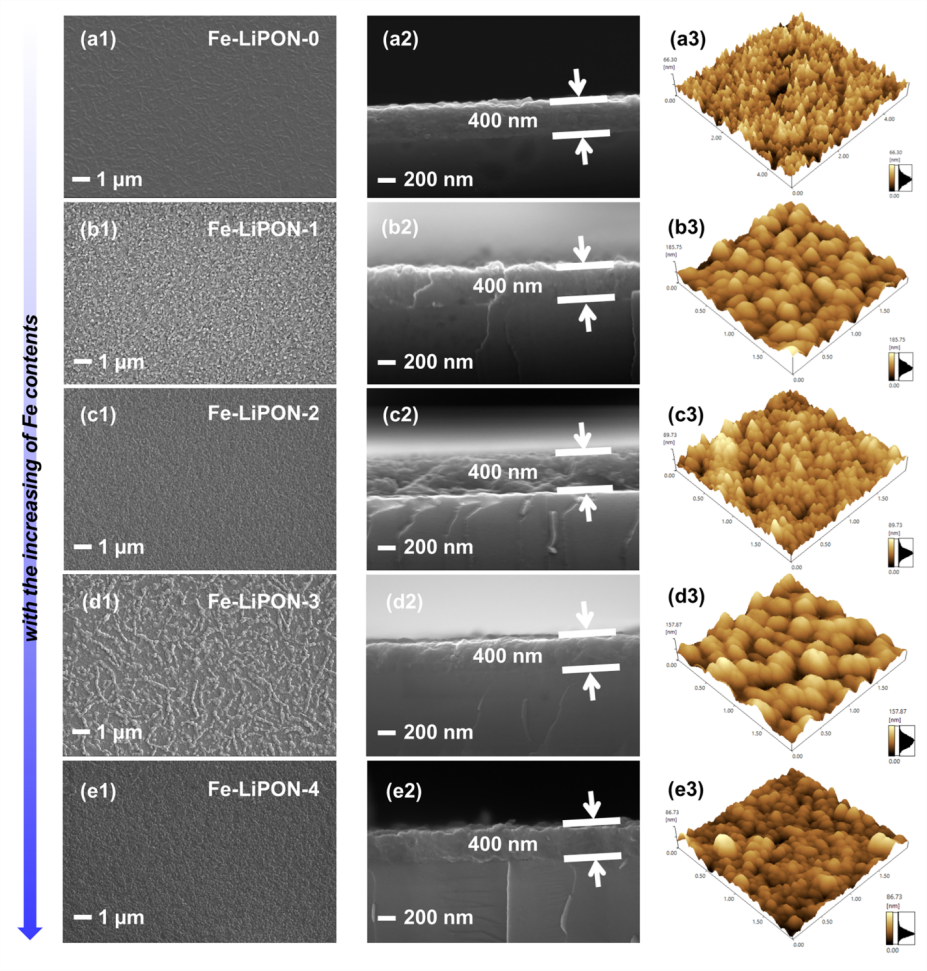

Figure 1 Surface, cross-sectional FESEM images and three-dimensional AFM diagrams of Fe-LiPON-0 (a), Fe-LiPON-0 (b), Fe-LiPON-2 (c), Fe-LiPON-3 (d) and Fe-LiPON-4 (e) films

Element doped modification of cathod thin films:

In order to meet the demand of portable microelectronic devices for high energy density and small-sized rechargeable battery systems, thin film materials with high specific capacity and good high-voltage cycling stability is designed and developed using radio frequency magnetron sputtering method, with low cost, high capacity, and long cycling as the core. Conduct in-depth research on the mechanism of RF magnetron sputtering coating and obtain technology for uniformly doping and modifying the cathode thin film materials; Study the effects of doping elements on the composition, structure, and properties of cathode thin film materials. On the basis of optimizing process steps and reducing costs, the preparation of high capacity and good cycling cathode thin film materials are achieved to solve the problem of low energy density in solid-state thin film batteries.

Our team develope high-voltage LiCoO2 thin films through Mg/Al co doping. Mg2+ doping played a supporting role in expanding interlayer spacing, while Al3+ doping further stabilized the LiCoO2 structure and improved the high-pressure structural stability of the material. The first cycle discharge specific capacity of doped thin films can reach 50.03 μAh cm-2. And the capacity retention rate for the first 100 cycles is 71.06%. In order to further improve the energy density of solid-state thin film batteries, our team use radio frequency magnetron sputtering method to reduce the degree of cation mixing in the NCM811 thin film through Zr/Al co doping modification, alleviating the changes in material volume during the cycling process. Doped NCM811 thin film with 187 mAhg-1 (60.00 μAh cm-2) at the same time as high specific capacity, the capacity retention rate for the first 100 cycle reached 72%.

Figure 1 (a) Cyclic performance of LCO and doped samples at 3-4.5 V; (b) Cyclic performance of NCM811 and doped samples at 3-4.5 V