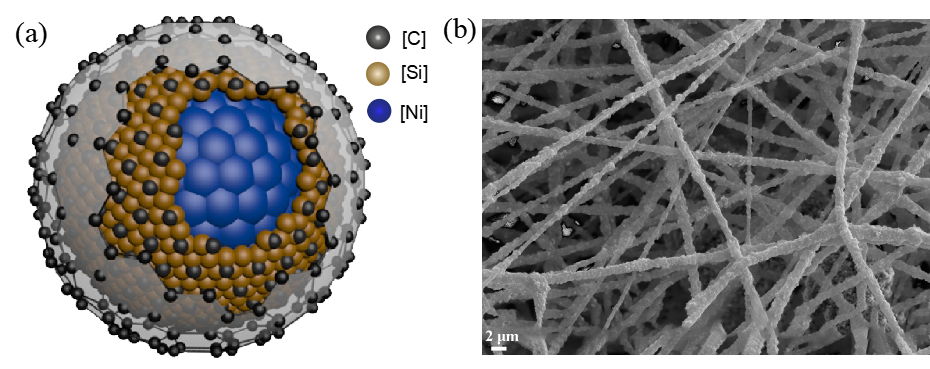

In response to the high standard requirements of super stealth of new generation warplanes, traditional microwave absorbing materials have narrow and uncontrollable absorption bands and poor mechanical properties of composite materials. The lab integrates the absorbing functional layer and structural layer into hot pressing, and prepares the functional-structural integrated stealth composite material to serve the intelligent stealth skin of the next-generation warplane. Firstly, the composite nanoparticles with dielectric loss and magnetic loss are prepared by the impedance matching principle and structural design. The functional nanoparticles are filled into the one-dimensional fibers by electrostatic spinning technology, and the integrated microwave absorbing functional layer and carbon fiber structural layer are formed into the structure by using vacuum hot-pressing tank. Focus on breaking through the single material can not achieve broadband absorption, poor mechanical properties and other "neck" problem.

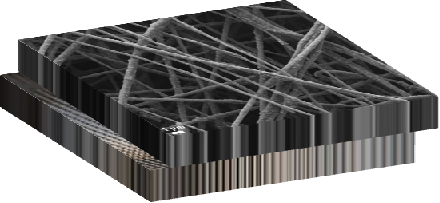

At present, the laboratory has achieved the mass preparation of multiple types of wave absorbing nanopowders (metallic monomers and alloys, carbon materials, non-metallic materials, etc.) to meet the full-band absorption requirements. The thickness of the stealth functional layer is controlled below 500 μm while ensuring all aerodynamic structural models and mechanical performance parameters of the vehicle. The composite material achieves a reflection loss of less than -15 dB for the full wavelength band (2-18 GHz). Compared with conventional coatings, the microwave absorbing functional layer has a weight reduction of 30-40 %. The design of the functionally integrated stealth composite provides a feasible solution for the preparation of stealth skins for new generation warplanes.

Fig.1. (a) Schematic diagram of nanoparticle structure, (b) SEM images of electrostatically spun nanofibers

Fig.2. Schematic diagram of functional-structural integrated stealth composite structure